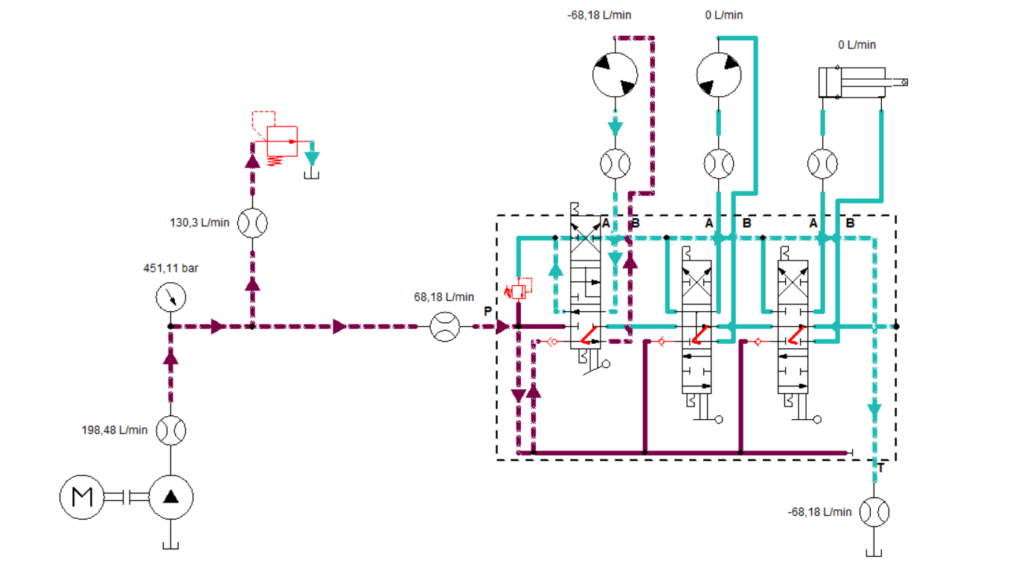

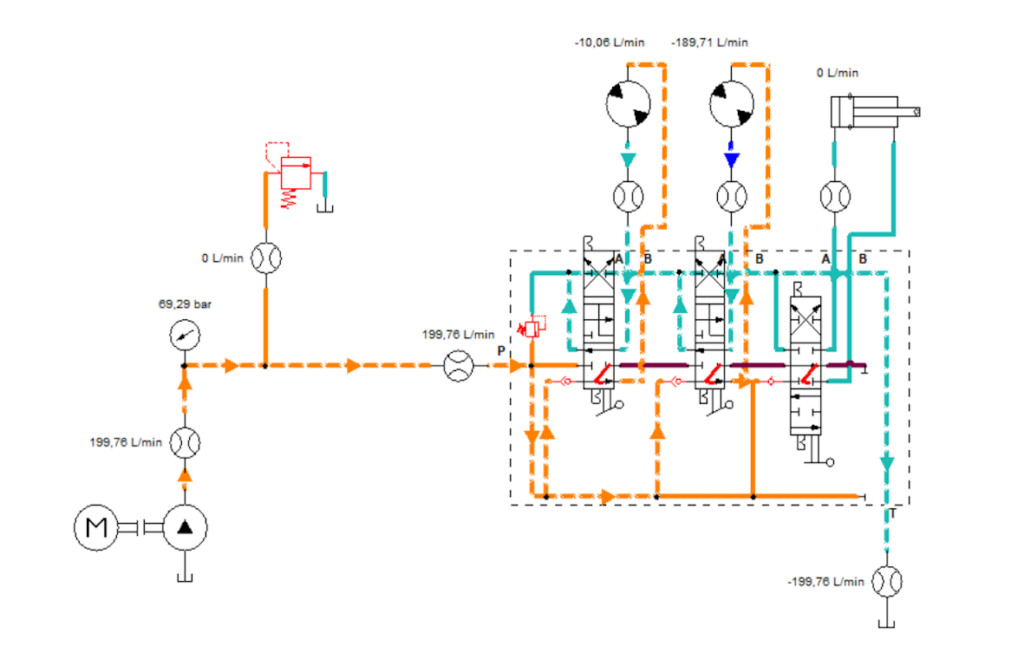

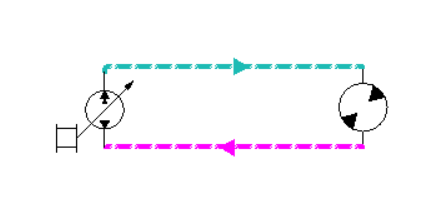

In this type of hydraulic circuit, the fluid from the piston pump flows directly to a motor and back to the pump without passing through the tank. The particularity of this type of circuit is its bidirectional operation. In fact, when the control lever is in the neutral position, there is no flow. When the lever is pushed forward, the pump will supply fluid to the motor and the motor will begin to turn. Gradually, the further the lever is pushed, the more fluid flows and the faster the motor will turn. Conversely, if the lever is pulled backwards, in the opposite direction, the fluid will move in the opposite direction, reversing the direction of rotation of the motor. This type of circuit makes it easier to control the speed and direction of the motor and has the advantage of being generally compact, light and efficient. The fluid that circulates in the circuit does not return to the tank but goes directly to the pump, unlike an open circuit. The oil that is pumped is 100% used.